150 à®à®©à¯ ஹà¯à®à¯à®°à®¾à®²à®¿à®à¯ ரபà¯à®ªà®°à¯ à® à®à¯à®à¯

150 à®à®©à¯ ஹà¯à®à¯à®°à®¾à®²à®¿à®à¯ ரபà¯à®ªà®°à¯ à® à®à¯à®à¯ Specification

- பவர்

- 200-250 வோல்ட் (வி)

- ஊடகம்

- Hydraulic Oil

- கட்டமைப்பு

- Four-Column, Heavy-Duty Frame

- பயன்பாடு

- தொழில்துறை

- பொருள்

- துருப்பிடிக்காத எஃகு

- ஏர் நுகர்வியம்

- உயர்

- வேகம்

- Adjustable

- தயாரிப்பு வகை

- 150 டன் ஹைட்ராலிக் ரப்பர் மோல்ட் பிரஸ்

- அதிகபட்ச முறுக்கு

- 150 Ton

- Cooling System

- Integrated Water Cooling

- Cycle Time

- 60-120 seconds

- Operating Voltage

- 380V / 50Hz

- Platen Size

- 900 mm x 900 mm

- Heating Plate Temperature Range

- Up to 300°C

- Control System

- PLC Controlled

- Oil Tank Capacity

- 450 Liters

- Daylight

- 800 mm

- Safety Features

- Emergency Stop & Safety Guards

- Pressing Force

- 150 Tons

- Weight

- Approximately 6,500 kg

- Stroke

- 500 mm

- Motor Power

- 11 kW

- Application

- Rubber Molding, Automotive and Footwear Industries

150 à®à®©à¯ ஹà¯à®à¯à®°à®¾à®²à®¿à®à¯ ரபà¯à®ªà®°à¯ à® à®à¯à®à¯ Trade Information

- Minimum Order Quantity

- 1 Unit

- வழங்கல் திறன்

- 50 மாதத்திற்கு

- டெலிவரி நேரம்

- 7 - 10 நாட்கள்

- பிரதான உள்நாட்டு சந்தை

- ஆல் இந்தியா

About 150 à®à®©à¯ ஹà¯à®à¯à®°à®¾à®²à®¿à®à¯ ரபà¯à®ªà®°à¯ à® à®à¯à®à¯

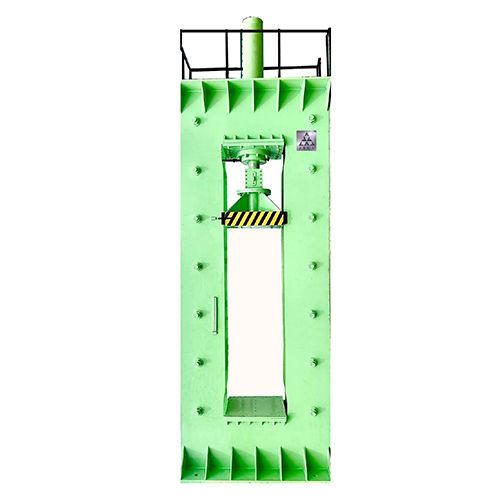

Capitalise on the inestimable precision and productivity of the 150 Ton Hydraulic Rubber Mold Pressengineered for the ultimate performance in automotive and footwear industries. Buy online and explore unrivaled efficiency with its vast 900 mm x 900 mm platen size, adjustable speed, and impeccable safety features. The PLC-controlled system, heavy-duty stainless steel four-column frame, and integrated cooling system ensure long-lasting reliability. With up to 300C heating plate range and rapid 60-120 second cycle time, this press is the superior choice for industrial rubber molding operations. Manufactured and exported from India.

Key Features and Industrial Usage

This 150 Ton Hydraulic Rubber Mold Press features an advanced PLC control system for precision and ease of use. Crafted with stainless steel, its heavy-duty four-column frame ensures durability and reliability under high-pressure loads. Designed for industrial-scale applications, it delivers an impressive 150 tons of pressing force, making it an unrivaled asset in rubber molding for automotive and footwear manufacturing. Adjustable speed, a large 900x900 mm platen, and safety guards further elevate operational efficiency.

Sample Availability & Export Markets

Samples of the 150 Ton Hydraulic Rubber Mold Press are available for customers to review before purchase, ensuring confidence in the inestimable quality. With a strong export market presence, this press is supplied to numerous international clients, reflecting its significant estimated market value. Domestically, it serves leading manufacturers across India, solidifying its reputation as a reliable and value-driven solution for rubber molding industries nationwide.

Key Features and Industrial Usage

This 150 Ton Hydraulic Rubber Mold Press features an advanced PLC control system for precision and ease of use. Crafted with stainless steel, its heavy-duty four-column frame ensures durability and reliability under high-pressure loads. Designed for industrial-scale applications, it delivers an impressive 150 tons of pressing force, making it an unrivaled asset in rubber molding for automotive and footwear manufacturing. Adjustable speed, a large 900x900 mm platen, and safety guards further elevate operational efficiency.

Sample Availability & Export Markets

Samples of the 150 Ton Hydraulic Rubber Mold Press are available for customers to review before purchase, ensuring confidence in the inestimable quality. With a strong export market presence, this press is supplied to numerous international clients, reflecting its significant estimated market value. Domestically, it serves leading manufacturers across India, solidifying its reputation as a reliable and value-driven solution for rubber molding industries nationwide.

FAQs of 150 Ton Hydraulic Rubber Mold Press:

Q: How does the PLC control system enhance the hydraulic presss performance?

A: The PLC control system provides precise command over temperature, pressure, and cycle time, ensuring consistent quality and safe operation during the rubber molding process.Q: What industries typically use the 150 Ton Hydraulic Rubber Mold Press?

A: This press is widely used in the automotive and footwear industries for rubber molding applications owing to its high pressing force and large platen size.Q: Where is this hydraulic rubber mold press manufactured and exported from?

A: The press is manufactured in India, serving both domestic and international export markets as a leading choice among manufacturers and suppliers.Q: What safety features are integrated into the rubber mold press?

A: It includes an emergency stop function and robust safety guards designed to protect operators during high-pressure molding operations.Q: What are the main benefits of using a heavy-duty four-column structure in the press?

A: The four-column, heavy-duty frame ensures optimal stress distribution, increased stability, and longevity for continuous industrial use.Q: When is it suitable to use the 150 Ton Hydraulic Rubber Mold Press?

A: It is ideal for use in high-volume industrial settings where consistent large-scale rubber molding is required, especially when rapid cycle times are essential.

- Minimum Order Quantity

- Supply Ability

- Delivery Time

- Main Domestic Market

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

மேலும் Products in மாற்று மற்றும் நியூமேடிக் பிரஸ் Category

50 டன் ஹைட்ராலிக் ஹோல் பஞ்சர்

வேகம் : மிமீ/வி

அதிகபட்ச முறுக்கு : என்மீ

அளவின் அலகு : அலகுகள்/அலகுகள்

பயன்பாடு : தொழில்துறை

பவர் : 200250 வோல்ட் (வி)

பொருள் : துருப்பிடிக்காத எஃகு

ஹைட்ராலிக் ஹால் பஞ்சர் பிரஸ்

வேகம் : மிமீ/வி

அதிகபட்ச முறுக்கு : என்மீ

அளவின் அலகு : அலகுகள்/அலகுகள்

பயன்பாடு : தொழில்துறை

பவர் : 200250 வோல்ட் (வி)

பொருள் : துருப்பிடிக்காத எஃகு

ஹைட்ரோ நியூமேடிக்

வேகம் : Adjustable

அதிகபட்ச முறுக்கு : Up to 5000 Nm

அளவின் அலகு : அலகுகள்/அலகுகள்

பயன்பாடு : தொழில்துறை

பவர் : 200250 வோல்ட் (வி)

பொருள் : துருப்பிடிக்காத எஃகு

அழுத்தத்தை மாற்றவும்

வேகம் : Moderate

அதிகபட்ச முறுக்கு : 35 Nm

அளவின் அலகு : அலகுகள்/அலகுகள்

பயன்பாடு : தொழில்துறை

பவர் : 200250 வோல்ட் (வி)

பொருள் : துருப்பிடிக்காத எஃகு

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு எஸ்எம்எஸ் அனுப்பவும்

எஸ்எம்எஸ் அனுப்பவும் என்னை இலவசமாக அழைக்கவும்

என்னை இலவசமாக அழைக்கவும்